Safe Solutions with high-pressure water mist

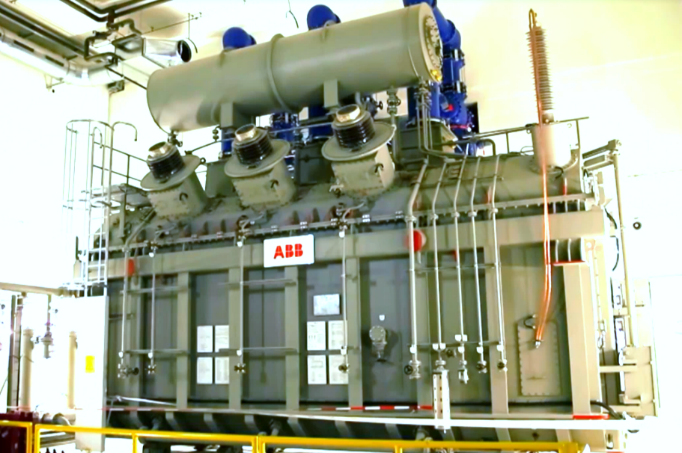

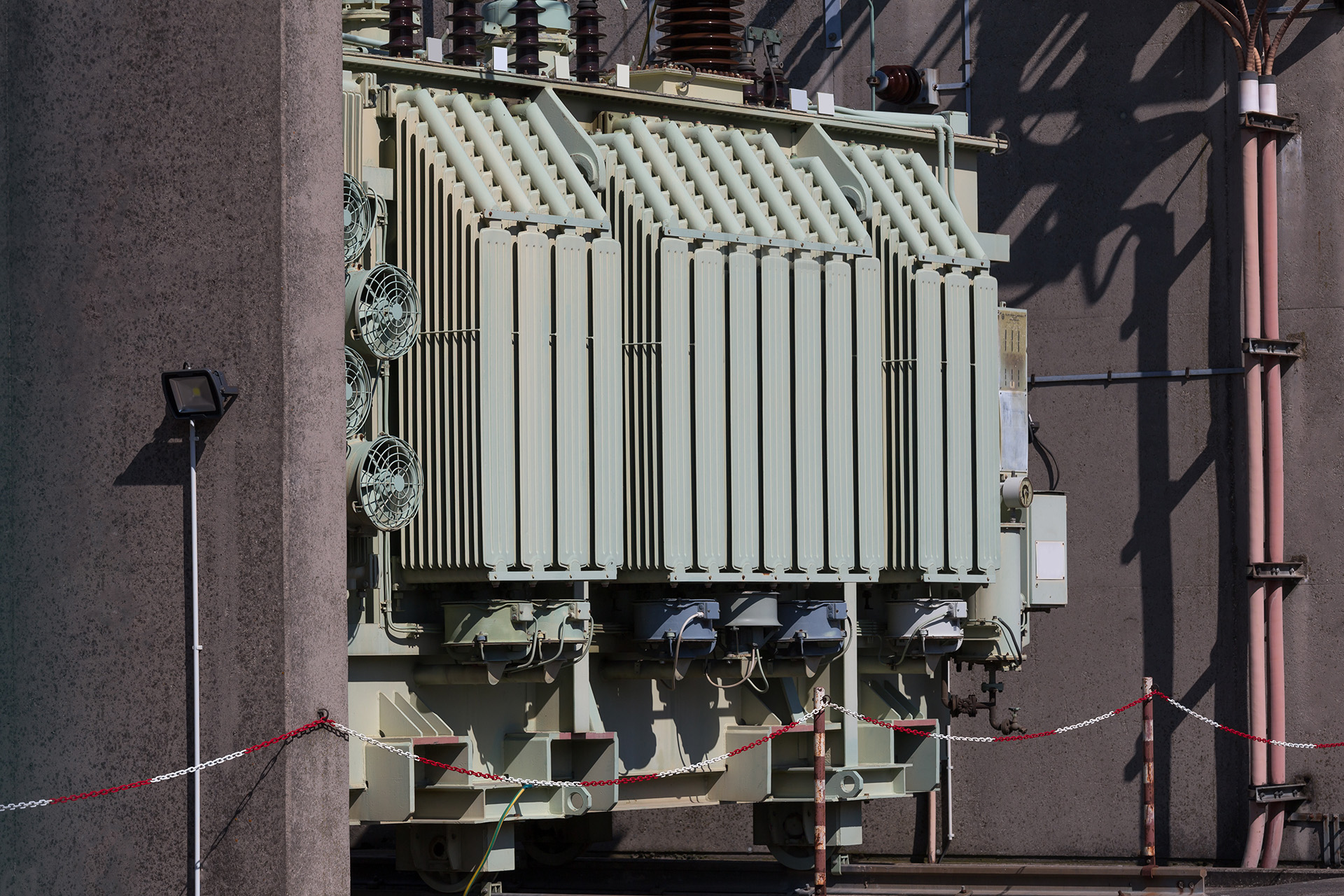

Transformers have an increased risk of fire due to the large quantities of energy and cooling oil involved in their operation. Fires in transformers and their surroundings are often caused by cooling oil leakages. These fires can lead to significant damage and, in the worst case, the complete destruction of the transformer. Long replacement times can significantly impair the operation of systems and cause major problems for operators.

pre-warning times requirement assures safe environment for people and minimal fire damage thus business interruption

cooling effect compared to any other firefighting agent assures safe environment for people and effectively avoids re-ignitions

Therefore, a well-designed fire protection concept for the transformer room or the entire transformer station is essential. High-pressure water mist systems are an effective solution. These systems can be designed for room or object protection and provide effective fire protection for transformers.

The fine atomisation of the water provides a high cooling effect while simultaneously reducing the oxygen concentration at the source of the fire. This effectively fights the fire.

FAQ – Fire Protection in Transformers

Why is water mist suitable for transformer fires?

Ultra-fine droplets provide intense cooling and locally reduce oxygen availability, effectively limiting fire spread and re-ignition in oil-involved transformer fires.

Room or object protection — how is it designed?

Water mist systems are project-specifically designed as either room or object protection (nozzle placement, pressure/pumps, fire detection integration), depending on oil volume, geometry, and protection concept.

Does water mist cause secondary damage?

Water volumes are significantly lower than conventional sprinklers, minimizing damage. Nevertheless, containment/collection systems for contaminated water and proper disposal are mandatory.

Standards, testing, maintenance — what is required?

Planning and verification must follow recognized technical standards. Certified nozzles and pumps, as well as regular inspections and maintenance, are mandatory. Documentation must be project- and standard-compliant.